Product Description

ORACAL® 351 Metallized Polyester Film | Kirin Global Supplies

Product Overview

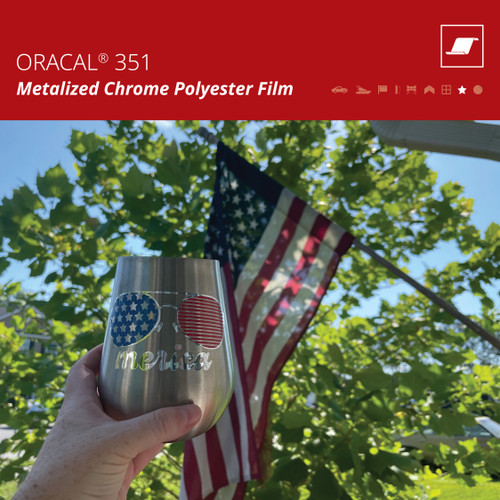

ORACAL® 351 Metallized Polyester Film is a 1-mil premium polyester film engineered for outstanding dimensional stability and long-lasting visual brilliance. Designed for both decorative and industrial use, it delivers the look of polished metal in Chrome, Matte Chrome, and Gold finishes—ideal for labels, nameplates, decals, and safety markings that demand precision and durability.

This high-performance film is backed by a clear, solvent-based permanent adhesive, ensuring consistent adhesion to metals, plastics, and painted surfaces. Its excellent tensile strength, temperature resistance, and self-extinguishing fire behavior make it a reliable choice for both functional and decorative applications.

Key Features

-

Film Type: Metallized polyester (1 mil)

-

Finishes: Chrome, Matte Chrome, and Gold coated

-

Adhesive: Clear, solvent-based permanent adhesive

-

Liner: 84 lb PE-coated silicone paper

-

Durability:

-

2 years (Chrome & Matte Chrome)

-

1 year (Gold coated)

-

-

Application Temperature: Minimum 46 °F (8 °C)

-

Temperature Resistance: -40 °F to +248 °F (no variation)

-

Tensile Strength: 200 MPa (along) / 300 MPa (across)

-

Elongation at Break: 120 % (along) / 85 % (across)

-

Fire Rating: ASTM E 84 Class A | DIN 75200 Self-Extinguishing

-

Seawater Resistance: No change after 100 hours at 73 °F

-

Conformability: Suitable for plotter-cutting systems

Recommended Applications

-

Decorative labels and emblems

-

Nameplates and technical data plates

-

Moldings, trims, and decorative elements

-

Safety and certification stickers

-

Retail packaging and product branding

-

Precision plotter-cut graphics

Available Sizes

-

Roll Lengths: 150 ft (50 yd) and 30 ft (10 yd)

-

Widths: 15 in (punched), 24 in, 30 in, 48 in

Recommended Transfer Tapes: ORATAPE® HT55, MT95, MT72, MT80P

Application Notes

Before application, ensure all surfaces are clean, dry, and free of dust, grease, or other contaminants. For freshly painted or lacquered surfaces, allow full curing before installation. Compatibility testing is recommended. Follow all ORAFOL® application guidelines to achieve optimal results.