Product Description

Copper Crest Illusion 70/30UV One-Way Vision Perforated Window Film - 6.5 Mil Economical PVC for Vehicle Glass & Storefronts - HP Latex Certified

Professional One-Way Vision at an Economical Price

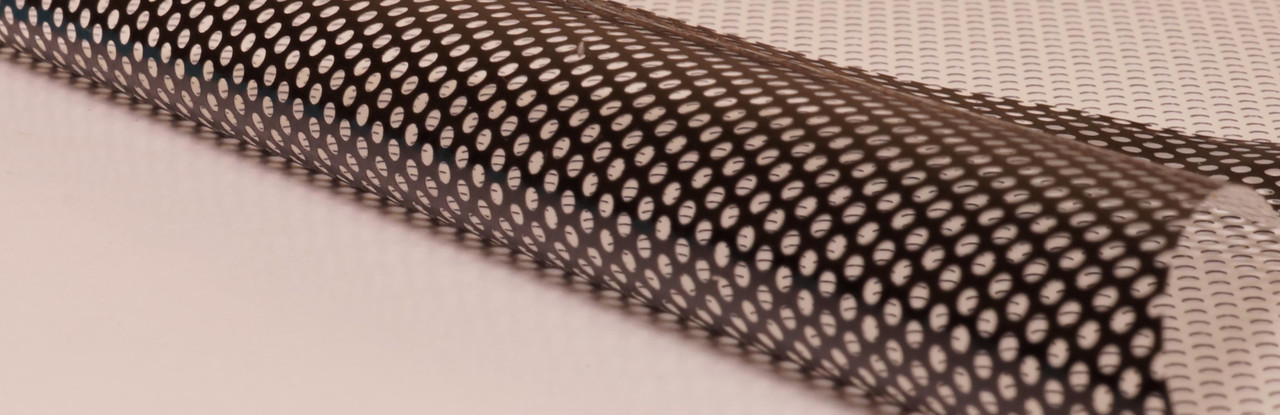

Copper Crest Illusion 70/30UV is an economical perforated window film engineered to transform vehicle glass, storefront windows, and other clear flat surfaces into vibrant advertising spaces while maintaining outward visibility. This 6.5-mil PVC film features a white printable face and laminated black back, utilizing a 70/30 perforation pattern (70% printable, 30% perforations) that delivers superior print quality and coverage compared to traditional 60/40 patterns. The proprietary construction enables universal printability across Eco Solvent, Latex, UV Cure, and UV Gel platforms, with HP Latex certification ensuring reliable performance on HP printing systems. With removable clear acrylic pressure-sensitive adhesive, good UV and abrasion resistance, and 2-5 year outdoor durability under normal conditions (with minimal residue remaining within 6 months), this one-way vision film provides professional results for fleet graphics, retail window advertising, building wraps, and privacy applications. The 50/50 construction (50% solid content with 1.5mm holes) creates the perfect balance between graphic impact from outside and clear visibility from inside. Available in convenient 54"x164' and 60"x164' rolls, Copper Crest Illusion 70/30UV delivers the performance and quality professional installers demand at a price point that makes one-way vision graphics accessible for budget-conscious projects.

One-Way Vision Technology Explained

How It Works

Perforated window film creates a "one-way vision" effect through a simple but effective principle:

From Outside (Bright Side)

Viewers see your printed graphic covering the window. The perforations are hidden by the printed surface and black backing, creating the appearance of a solid, opaque graphic.

- ✓ Full-color graphics visible

- ✓ Professional advertising impact

- ✓ Maximum brand exposure

- ✓ Perforations virtually invisible

From Inside (Dark Side)

Occupants see clearly through the perforations to the outside. The black backing and lower interior light levels make the printed surface nearly invisible from inside.

- ✓ Clear outward visibility

- ✓ Maintained natural light

- ✓ Privacy from outside view

- ✓ Unobstructed sightlines

⚠️ Important: One-way vision effect works best when the outside is brighter than the inside. At night with interior lights on, the effect reverses—people outside may see in. For nighttime privacy, consider interior lighting solutions or blinds.

70/30 Perforation Pattern Advantage

Why 70/30 Outperforms 60/40

Copper Crest Illusion uses a 70/30 pattern (70% printable, 30% perforations) that provides significant advantages:

Superior Print Quality

16% more printable surface area than 60/40 patterns delivers richer colors, better coverage, and more impactful graphics from the outside.

Better Graphic Coverage

More solid area means your message and branding are more visible and legible from greater distances and angles.

Enhanced Privacy

Less open area provides better daytime privacy while still maintaining excellent outward visibility from inside.

Balanced Performance

Optimal balance between graphic impact (outside view) and visibility (inside view) for professional applications.

50/50 Construction: 50% solid content with 1.5mm holes provides the perfect engineering for one-way vision effect.

Key Features & Benefits

- 70/30 Perforation Pattern: Superior print quality vs. 60/40 patterns

- 6.5 Mil PVC Film: Substantial thickness for durability

- White Print Face/Black Back: Optimized for one-way vision effect

- Removable Adhesive: Clear acrylic pressure-sensitive adhesive

- 2-5 Year Outdoor Durability: Reliable performance under normal conditions

- Minimal Residue: Clean removal within 6 months

- Good UV Resistance: Protection against sun damage and fading

- Good Abrasion Resistance: Withstands handling and environmental exposure

- HP Latex Certified: Guaranteed compatibility with HP Latex printers

- Universal Printability: Eco Solvent, Latex, UV Cure, UV Gel compatible

- Optional Clear Laminate: Optically clear PSA laminate for added protection

- Economical Solution: Professional results at budget-friendly price

Applications

Vehicle Graphics

- Fleet vehicle rear windows

- Van side and rear windows

- Bus advertising windows

- Commercial vehicle branding

- Delivery vehicle graphics

- Service vehicle windows

- Trailer rear window graphics

Storefront Windows

- Retail window advertising

- Restaurant window graphics

- Promotional window displays

- Store window branding

- Seasonal window promotions

- Sale and event graphics

- Privacy window graphics

Building Applications

- Building window wraps

- Office window privacy

- Conference room windows

- Glass partition graphics

- Lobby window advertising

- Facility window branding

- Multi-story building graphics

Transit Advertising

- Bus window advertising

- Transit shelter graphics

- Train window advertising

- Subway car windows

- Airport shuttle graphics

- Public transit branding

- Mobile advertising campaigns

Technical Specifications

| Film Type: | PVC Perforated One-Way Vision |

| Thickness: | 6.5 mil (+/- 0.005mm) |

| Weight: | 160 g/m² (including adhesive) |

| Print Face: | White |

| Back: | Laminated Black |

| Perforation Pattern: | 70/30 (70% printable, 30% perforations) |

| Solid Content: | 50% (50/50 construction) |

| Hole Size: | 1.5 mm |

| Adhesive: | Removable clear acrylic pressure-sensitive |

| Final Tack: | 5 hours (stainless steel) |

| 180° Pull Force (24h): | 8N |

| Outdoor Durability: | 2-5 years under normal conditions |

| Removability: | Minimal residue within 6 months |

| Shelf Life: | 1 year |

| Application Type: | First surface (exterior application) |

Available Sizes

- 54" x 164' (1.37m x 50m)

- 60" x 164' (1.52m x 50m)

Print Compatibility

✓ HP Latex Certified Product

Copper Crest Illusion 70/30UV features proprietary construction allowing universal printability across all major ink platforms:

HP Latex Printing

Certified for HP Latex printers!

- Printer Media Choice: Self Adhesive or Copper Crest Perforated Window Film

- RIP OMS Profile: Self-adhesive Vinyl or Copper Crest Illusion Perforated Window Film

- Mode: 12pb_600-2bpp_stochastic

- Rendering Intent: Saturation

Solvent & Eco-Solvent

Compatible with Mild-Solvent and Eco-Solvent platforms

- Media Setting: Copper Crest Illusion Perforated Window Film or Standard Perforated Window Film/PSA vinyl

- Heater Settings: 45°C - 50°C suggested

- Dry to Touch: 5-10 minutes

- Drying Tip: External dryer or heat lamps accelerate drying

UV Cure & UV Gel

Excellent compatibility with UV curing systems

- Instant curing for fast production

- Superior outdoor durability

- Brilliant color reproduction

Optional Clear Overlaminate

For added protection and easier handling, an optically clear PSA laminate can be applied to the face:

- Enhanced Protection: Guards against scratches, UV, and abrasion

- Easier Handling: Stiffens material for easier installation

- Extended Life: Prolongs outdoor durability

- Professional Finish: Smooth, polished appearance

- Moisture Resistance: Additional barrier against environmental elements

Note: Laminate must be optically clear to maintain one-way vision properties.

Handling & Storage

⚠️ Important Handling Considerations

Perforated materials are more delicate than solid films because there is less surface adhering to the liner:

- Avoid Repeated Bending: Don't fold or crease material—it can cause delamination

- Temperature Acclimation: Allow material to adjust to room temperature before printing

- Careful Unwinding: Handle rolls gently to prevent separation from liner

- Flat Storage: Store printed graphics flat when possible

- Gentle Handling: Use care during transport and installation

Storage Recommendations

- Store in original packaging until use

- Keep at moderate room temperature

- Protect from direct sunlight and temperature extremes

- Shelf life: 1 year from date of manufacture

- Store horizontally to prevent roll deformation

Installation Guidelines

Pre-Installation Testing

HIGHLY RECOMMENDED: Prior to full installation, attach a small test piece of perforated film to the window to:

- Become familiar with film characteristics

- Assess adhesion strength on actual substrate

- Verify one-way vision effect in actual lighting conditions

- Practice application technique

Surface Preparation

- Clean Windows Thoroughly: Pay special attention to edges, removing all dirt, dust, and sealant

- Use 85% Isopropyl Alcohol: Remove any residue and allow to evaporate completely before installing

- NEVER Use Ammonia or Windex®: These can interfere with adhesive bonding

- Scrape Off Debris: Use razor blade at 45° angle to remove leftover dirt or bug residue

- Final Cleaning: Use lint-free cloth or commercial paper towels to completely dry glass

- Verify Temperature: Glass temperature must be moderate—between 40°F and 80°F

Temperature Considerations

- Avoid Very Warm Conditions: Hot glass may cause film to stretch during installation

- Avoid Direct Sunlight: Heat can affect adhesive performance and cause stretching

- Cold Weather Installation: Apply film mid-day after windows have warmed

- Too Cold = Poor Adhesion: Low temperatures adversely affect adhesive bond

Application Methods

Dry Application (Smaller Panels - Recommended)

- In most cases, product can be applied dry

- Better control and faster installation

- No waiting for application fluid to evaporate

- Suitable for most window sizes

Wet Application (Larger Panels - Optional)

- Small amount of Rapid Tac professional application fluid can assist installation

- IMPORTANT: Unlaminated graphics only

- Allows repositioning on large panels

- Reduces risk of stretching

- CRITICAL: Make sure all fluid has completely evaporated shortly after installation

Critical Installation Rules

- NEVER STRETCH GRAPHICS: Calendered vinyl has memory and will try to return to original size, causing edge lifting

- SEAL EDGES: Use clear tape or liquid edge seal to prevent moisture intrusion and edge lifting

- MULTI-PANEL INSTALLS: Butt edges together—DO NOT overlap

- SMOOTH APPLICATION: Use proper squeegee technique to ensure contact in perforations

Edge Sealing - Critical for Longevity

Edge sealing is highly recommended for perforated window films to prevent:

- Moisture intrusion at edges

- Edge lifting due to vinyl memory

- Premature failure at perimeter

- Dirt and debris accumulation

Edge Sealing Options

- Clear Vinyl Tape: Apply 1/4" to 1/2" clear tape along all edges

- Liquid Edge Sealer: Brush-on sealant for permanent edge protection

- Trim-in-Place: For vehicle windows, trim carefully at edge of glass

Multi-Panel Installation

Proper Panel Joining Technique

For large windows requiring multiple panels:

- Butt Seams: Place edges directly against each other

- DO NOT OVERLAP: Overlapping creates visible seams and reduces transparency

- Precise Trimming: Ensure perfectly straight edges for clean butt seams

- Pattern Matching: Align graphics carefully across panels for seamless appearance

- Sequential Installation: Install panels in logical order for best alignment

Nighttime & Lighting Considerations

Understanding the One-Way Vision Effect

The one-way vision effect depends on light differential between inside and outside:

Daytime (Normal Conditions)

- ✓ Outside is brighter than inside

- ✓ Graphics visible from outside

- ✓ Clear visibility from inside to outside

- ✓ Privacy maintained from outside view

Nighttime (Interior Lights On)

- ⚠️ Inside becomes brighter than outside

- ⚠️ Effect reverses—people outside may see in

- ⚠️ Reduced privacy from outside view

- ⚠️ Graphics less visible from outside

Nighttime Privacy Solutions

- Dim or turn off interior lights when privacy needed

- Use blinds or curtains for nighttime privacy

- Install exterior lighting to maintain brightness differential

- Consider application location and usage patterns

Durability & Performance Expectations

2-5 Year Outdoor Durability

Under normal conditions, expect reliable performance for 2-5 years. Actual lifespan depends on:

- UV Exposure: Direct sunlight vs. shaded locations

- Climate: Moderate vs. extreme weather conditions

- Orientation: Vertical surfaces vs. angled or horizontal

- Maintenance: Regular cleaning vs. neglect

- Installation Quality: Proper technique vs. stretched or poorly sealed edges

- Substrate: Glass condition and preparation quality

Removal & Residue

Removable adhesive characteristics:

- Within 6 Months: Minimal residue expected with proper removal technique

- Heat Assistance: Use heat gun or steamer for easier removal

- Residue Removal: Any remaining adhesive can be cleaned with appropriate solvents

- Glass Protection: Removable adhesive protects glass during removal process

Product Highlights

- ✓ 70/30 perforation pattern - superior print quality vs. 60/40

- ✓ 6.5 mil PVC film - substantial durability

- ✓ HP Latex certified - guaranteed HP compatibility

- ✓ Universal printability - Eco Solvent, Latex, UV Cure, UV Gel

- ✓ White print face/black back - optimized for one-way vision

- ✓ Removable adhesive - clean removal within 6 months

- ✓ 2-5 year outdoor durability - reliable long-term performance

- ✓ Good UV resistance - protection against sun damage

- ✓ Good abrasion resistance - withstands environmental exposure

- ✓ Optional clear laminate - added protection and easier handling

- ✓ Economical solution - professional results at budget-friendly price

- ✓ First surface application - exterior installation on glass

Why Choose 70/30 Over 60/40?

| Feature | 70/30 Pattern (This Product) | 60/40 Pattern |

|---|---|---|

| Printable Surface | 70% - More graphic coverage | 60% - Less graphic area |

| Print Quality | Superior - 16% more print area | Standard |

| Graphic Impact | Higher - Better coverage | Lower - More see-through |

| Inside Visibility | Excellent - 30% open | Better - 40% open |

| Daytime Privacy | Better - Less open area | Good - More open area |

| Light Transmission | Good - Adequate natural light | Better - More light |

| Best For | Advertising, branding, high-impact graphics | Maximum visibility from inside |

Frequently Asked Questions

Q: How does one-way vision film work?

A: The perforations allow you to see through from the dark side (inside), while the printed surface and black backing make it opaque from the bright side (outside). This effect relies on light differential—it works during the day when outside is brighter, but reverses at night with interior lights on.

Q: What's the advantage of 70/30 over 60/40 perforation patterns?

A: 70/30 provides 16% more printable surface area than 60/40, resulting in superior print quality, better graphic coverage, more impactful advertising, and enhanced daytime privacy while still maintaining excellent outward visibility from inside.

Q: Can people see inside my vehicle/building at night?

A: Yes, potentially. The one-way vision effect reverses when the inside is brighter than outside (like nighttime with interior lights on). For nighttime privacy, dim interior lights or use blinds/curtains.

Q: Is this product HP Latex certified?

A: Yes! Copper Crest Illusion 70/30UV is HP Latex certified. Use "Self Adhesive" or "Copper Crest Perforated Window Film" as your printer media choice for optimal results.

Q: Should I apply this film wet or dry?

A: For smaller panels, dry application is recommended for better control and faster installation. For larger panels, a small amount of Rapid Tac application fluid can be used (unlaminated graphics only) to prevent stretching, but ensure fluid completely evaporates shortly after installation.

Q: Why is edge sealing important?

A: Edge sealing prevents moisture intrusion, edge lifting (especially important since calendered vinyl has memory), premature failure, and dirt accumulation. Use clear tape or liquid edge sealer on all edges for maximum longevity.

Q: Can I install this in cold weather?

A: Glass temperature should be between 40°F and 80°F for optimal adhesion. In cold weather, install mid-day after windows have warmed. Temperatures below 40°F can adversely affect adhesive bonding.

Q: What happens if I stretch the film during installation?

A: Never stretch perforated film! Calendered vinyl has memory and will try to return to its original size, causing edge lifting and eventual failure. If film is stretched during installation, it will likely fail prematurely.

Q: Do I need to overlaminate perforated window film?

A: Overlamination is optional but recommended for added protection and easier handling. If you choose to laminate, you MUST use an optically clear laminate to maintain the one-way vision properties. Never use matte or opaque laminates.

Q: How do I remove perforated window film?

A: Use a heat gun or steamer to warm the film, then peel slowly at a sharp angle. Within 6 months of installation, minimal residue should remain. Any adhesive residue can be removed with appropriate solvents and a plastic scraper.

Q: Can I overlap panels for large windows?

A: No! Always butt seams—do not overlap. Overlapping creates visible seams and reduces transparency from inside. Trim panels for perfectly straight edges and place them directly against each other.

Q: Why is my perforated film delaminating from the liner?

A: Perforated materials are more vulnerable because there's less surface adhering to the liner. Avoid repeatedly bending or creasing the material. Allow it to acclimate to room temperature before printing, and handle gently during transport and installation.

Quality Assurance

Copper Crest by Kirin Global Supplies is committed to providing high-quality graphic media solutions. This product is manufactured to professional standards and tested for performance. Actual results may vary based on substrate preparation, installation technique, environmental conditions, and ink systems used. We recommend testing on actual substrates before full production.